JC Super Props Details

Wood Propellers by JC Super Props |  |

JC Super Props selects their raw material very carefully. It is crucial to choose only the highest wood quality from the right part of the tree to consistently produce a strong and non warping high performance propeller. Before JC Props start production they allow their wood supply to dry for 6 months in a storage facility. |

Based on JC Props ongoing research and development to provide the model airplane industry with the best propellers they chose “Kuntze” tropical hard wood for their propeller production. Kuntze is a dark brown wood and is very strong despite being of low weight.The result is a light propeller, which is more responsive to throttle commands as the “Flying Wheel Effect” is greatly reduced. JC Super Props are perfect for 3D flight. JC Super Props has more than 20 years of experience, the knowhow, experience and manufacturing equipment to develop and manufacture any type of propeller in terms of pitch, diameter (up to 43”), tractor or pusher configuration. |  |

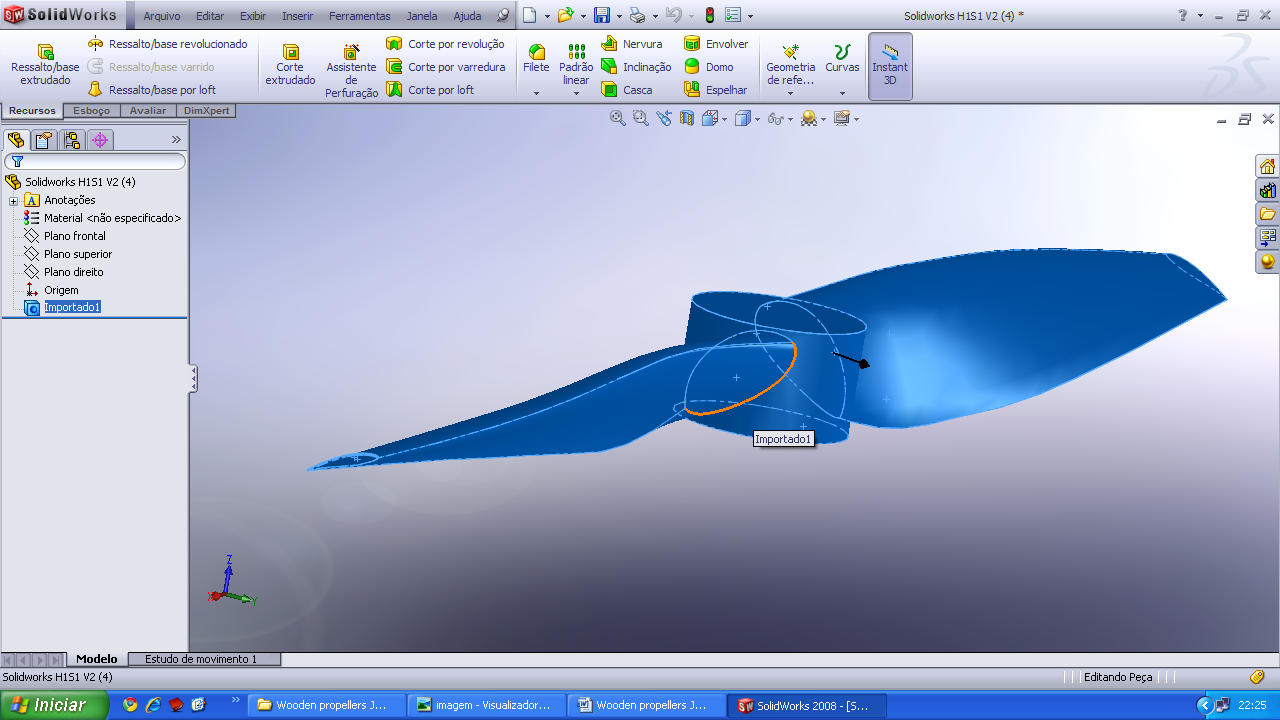

JC Super Props are manufactured by automated CNC machines designed exclusively for this purpose.

Specialized software is being used to develop all JC super props.

All parameters are calculated to maximize efficiency of JC propellers and the prop profiles are shaped to enable todays high-powered engines deliver maximum performance while minimizing noise as much as possible.

JC Super props are finished by hand. Each propeller undergoes a torsion and rupture test and a strict quality control procedure.

JC Super props receive three coats of a special waterproofing sealer to protect them against natural wood moisture. Then each propeller is balanced one by one. As a final step, the props receive two coats of varnish to protect against oils and gasoline.

The result is a high performance furniture quality propeller. The smooth high gloss finish of JC Super props improves air penetration and increases traction while reducing noise levels.